The 3-in-1 solution for your soldering process

Vision TripleX: a patented new development in the field of convection and vapor phase soldering. The system is based on the reflow convection soldering systems in the Vision series and combines the convection soldering process with the proven vapor phase soldering process of the Condenso series. Thus, three processes can be carried out in the Vision TripleX: reflow convection soldering with and without vacuum and vapor phase soldering using Galden®. This provides uniquely flexible manufacturing options.

Vacuum chamber

Vacuum soldering is one of the three soldering processes integrated in the Vision TripleX. In just one process, a vacuum module enables convection soldering processes to be carried out with a vacuum. This reliably removes pores, gas occlusions and voids immediately after the soldering process whilst the solder is still in its optimal molten state. Complex processing of the assembly via an external vacuum system is no longer necessary and the workpieces are moved straight into the vacuum process from the peak zones.

Active Galden® filtering

After soldering, the assembly is passed onto the cooling process. Process gas is extracted and cleaned at the same time. Therefore, a large part of the Galden® can be reused, a solution that is particularly material-friendly and environmentally friendly! A vacuum is created during extraction which also ensures that soldering material is dried quickly.

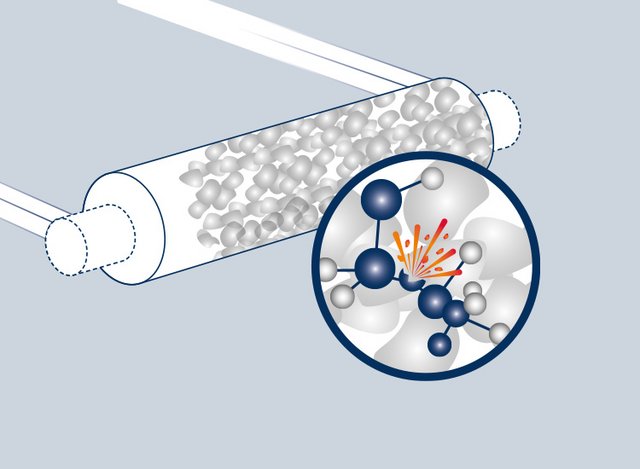

Pyrolysis

During the soldering process, substances that are released from circuit boards, solder paste or components must be filtered out of the process gas. This is why the Vision TripleX has a residue management system which recycles and cleans the process gas in the system. It combines the effect mechanisms of pyrolysis in the preheating and peak range with cold condensation in the cooling zone. The pyrolysis is set up so that it only needs to be cleaned once a year, which results in long maintenance cycles, as well as a clean and dry process chamber.