A global leader with innovative technologies

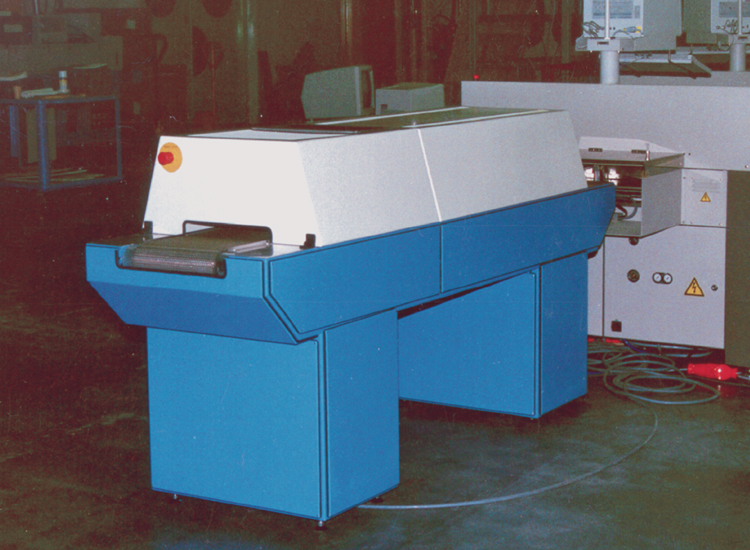

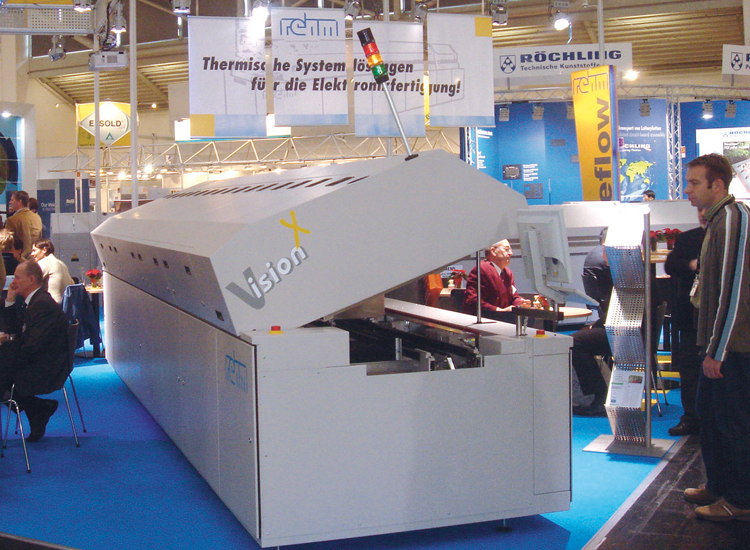

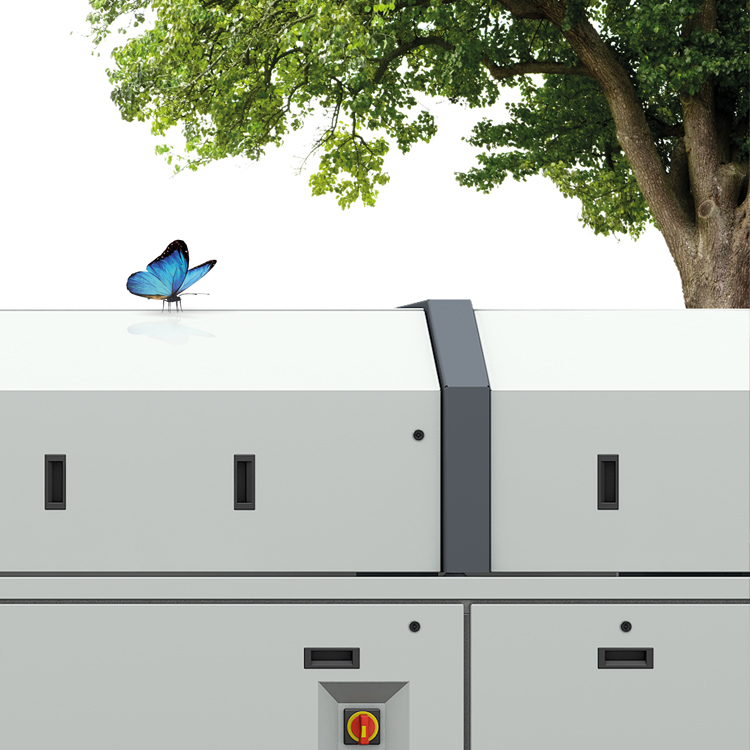

As a manufacturer of reflow soldering systems with convection or condensation and drying and coating systems, Rehm Thermal Systems has been producing energy-efficient manufacturing equipment for the electronics and photovoltaics industry since 1990. We also offer our customers tailor-made applications related to the soldering, coating and hardening of modules.

From our German headquarters in Blaubeuren, we coordinate the activities of our 26 locations in 24 countries worldwide. The company also set up an additional manufacturing facility in China in 2008. Our production facilities are state-of-the-art and are safeguarded by strict quality assurance guidelines in accordance with German standards. This enables us to serve the international markets quickly and to offer outstanding on-site service.

In addition to Rehm Thermal Systems, the Rehm Group includes the subsidiaries Rehm BlechTec, which specialises in processing stainless steel, aluminium and steel plate, and H+R Personaldienste GmbH. We are therefore a one-stop shop for all the services you need, from planning and design to the finished equipment.

We deliver the highest quality for your production facility: this is a key element of our company philosophy. The satisfaction of our clients is our measure of success and it runs through every detail of our production.

Excellent quality

Our systems are regularly certified to ISO standards, ensuring that every single part meets the requirements in terms of precision. Rehm BlechTec has been distinguished as a specialist soldering facility for many years by strict quality criteria; thanks to its excellent metal processing it provides the best possible conditions. We also plan and design all our machines with CE conformity in accordance with specified machinery directives.

Quickly and safely to the destination

The European regulations require a high level of security in terms of air cargo. All freight shipments must be strictly controlled and individually checked prior to loading. This process is associated with complex security regulations and thus with time and money. As an officially registered, well-known consignor, we ship our products reliably with authorisation from the German Federal Aviation Administration. Our systems and accessories which are ready for consignment are thus reliably secure before they even leave company premises. As a well-known consignor, Rehm had to implement clear guidelines in the company to achieve this, for example, the appointment of an air cargo security officer, extensive staff training and the establishment of a closed security zone. When it comes to customs clearance, our shipments are thus processed much more quickly and cost effectively.

„FutureSport“

To be able to master the challenges of tomorrow, a person needs to be fit, in every sense. For a number of years now, Rehm has supported various sports and health projects through financial donations and donations in kind as part of the “FutureSport” project run throughout Germany.

Mentoring and education partnership

Since 2007 we have been involved in a mentoring project with the Karl-Spohn-Realschule school in the Gerhausen district of Blaubeuren and we have had an education partnership with the Blautopfschule Blaubeuren school since the start of 2018.

Karopack® – clever packaging

To ensure that our equipment and spare parts reach our customers safely and without any damage, we use the safe and particularly sustainable Karopack® system with optimum padding. This system uses old cardboard boxes as filling material.