Vacuum contact soldering – perfect for power electronics

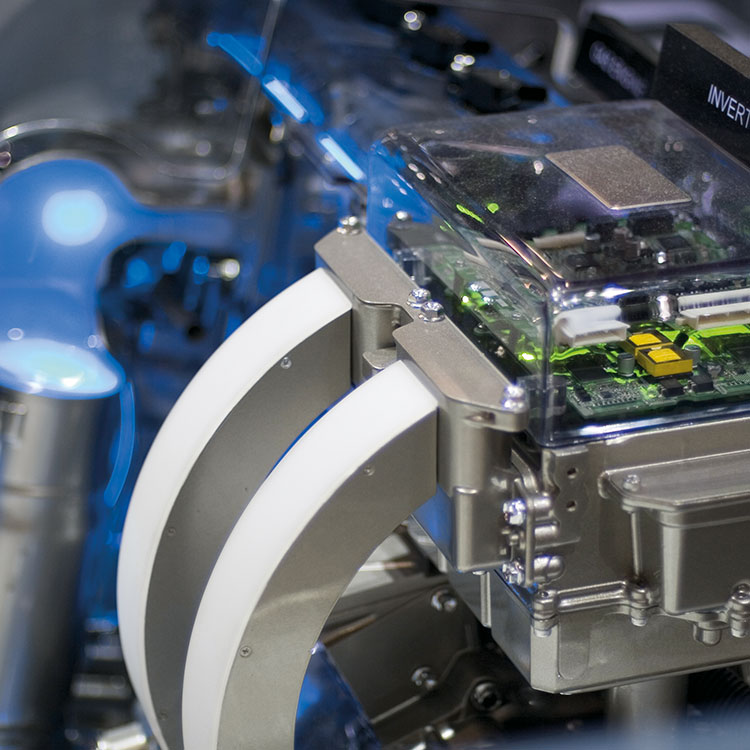

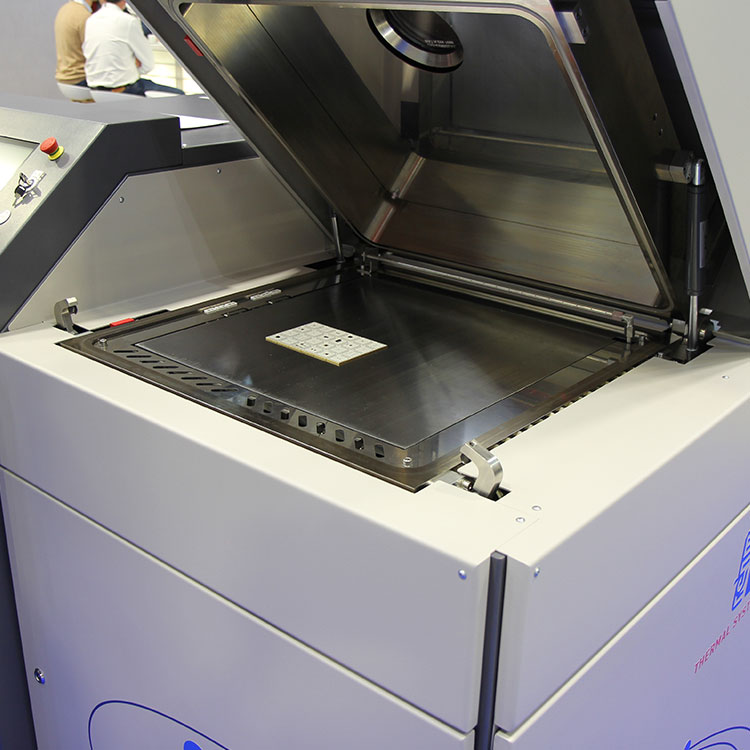

The Nexus soldering system guarantees the best results with a reflow soldering process using contact heat in a vacuum. This enables you to meet the highest requirements in the field of advanced packaging and power electronics. Productivity increases and quality advantages are achieved in the manufacturing of these components like this. In this way, the vacuum ensures oxide-free processes, as well as improved wetting and thus better filling of soldered joints. In addition, the vacuum drastically reduces the voids in soldered joints and enables processes such as plasma cleaning and atmosphere exchange for advanced packaging. Temperatures of up to 400°C can be used as standard.

for more sustainability

Areas of application for the contact soldering process

The areas of application for the contact soldering process are very diverse. As a result of the increasing demand for alternative energy, the demand for power electronics, semiconductors and wafer technology is also increasing.

These are increasingly being used for rail drive systems, wind power systems, battery storage and, not least, the automobile industry. In order to meet the increasing requirements which are being made of these modern power modules, hybrid and multichip components in terms of reliability and safety, the contact soldering process is the method of choice. Its compact dimensions and high level of user-friendliness mean that the system is particularly suitable for use in small-scale and medium-scale production, as well as in laboratories.

Why contact heat?

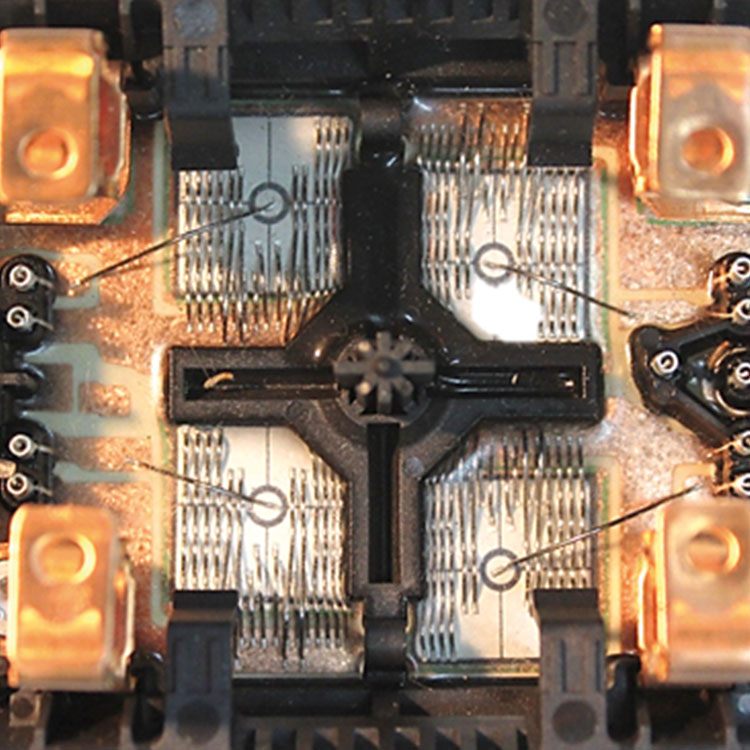

- Oxide-free and void-free joint surface between chip and circuit carrier

- Integrated or separate implementation of cleaning and descaling processes

- Rapid heating and cooling

- Housing assembly under variable vacuum conditions

- Integration of drying and degassing processes

- Improved dispersal of waste heat in void-free connections