Safety and the right quality

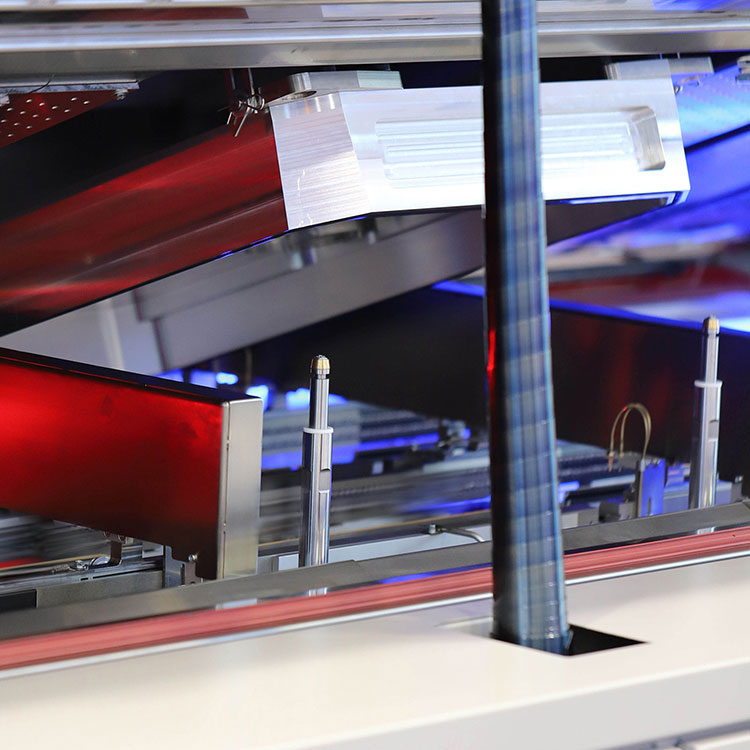

For full functionality of sensitive electronics, contact between the electrical components and the circuit board, created by high-quality soldering, is essential. With the convection soldering systems in the Vision series, the soldering process is carried out on the basis of heat transfer via the flow of gases. The systems are available as air or nitrogen systems. As an inert, protective gas, nitrogen is the ideal heat transfer medium and thus prevents damaging oxidation in the soldering process. Thanks to a wide range of possible system configurations, you achieve optimum quality with the Vision series convection soldering systems, as well as maximum flexibility in terms of your production.

for every manufacturing environment

The right system for every application

Our Vision series convection soldering systems are as varied and flexible as your manufacturing processes. Whether you choose VisionXP+ with or without a vacuum, VisionXS or the compact VisionXC:

We will work with you to take all the relevant parameters into consideration in order to find the most efficient system for you. One of the most important sizes in this regard is the throughput which is decisive in determining the optimum process zone length. We also focus on any regular product change or multiple-shift operation in your manufacturing environment. After considering all the parameters which are relevant to the process, you can be sure that you will be offered a reflow soldering system that has been tailored to your needs and with which you can manufacture your products reliably and efficiently. Thanks to the wide range of options within the Vision series, the right system is available for each manufacturing environment.

Why convection?

- Maximum process stability, even with unleaded soldering

- Modular, flexible system concept

- Energy-efficient systems with low CO2 emissions

- Minimum downtime and low maintenance costs

- Excellent traceability thanks to clever software tools

- Low "Total Cost of Ownership"