The highly flexible system structure means that two processes can be operated with the ProtectoXC and as many as four with the ProtectoXP. This allows you to combine a number of different applications within one machine. Besides sealing the entire PCB, it is also possible to mould only partial areas or individual components on the carrier. This results in a wide range of application possibilities, from “Globe Top” to “Dam & Fill” to “Flip Chip Underfill”. With innovative nozzle technology, the user can apply a very wide range of materials to the assembly, meaning that each product meets the precise requirements for optimum protection at a later stage.

Dam & Fill / 3D application

In the “Dam & Fill” process, two materials of different viscosities are used. Initially, a high-viscosity material is used to place a dam around the component which needs protecting. If a UV-curing material is used for this, it can also be cured directly using a suitable UV spot (only with ProtectoXP). Then the component can be encapsulated using a low-viscosity material in the same work process.

Densities

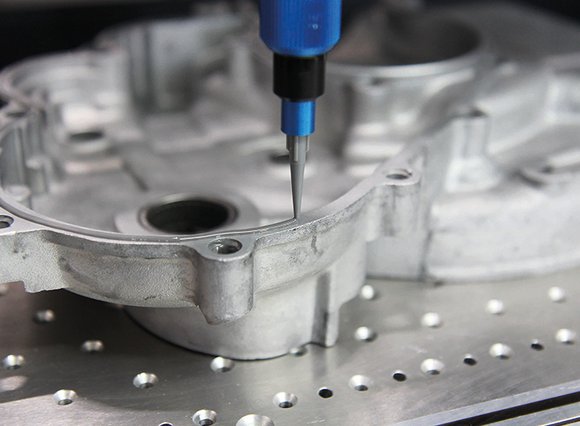

In this process, a 1K or 2K material (2K only with ProtectoXP) is applied to a component such that a continuous and even sealing bead is created. Volumetric applicators (only with ProtectoXP) are particularly good for this.

Globe Top

A “Globe Top” is intended to protect a selective area on the circuit board. A material is used for this that is fluid enough to safely encapsulate all the relevant components but that does not have such a low viscosity that it flows onto neighbouring components too.

Flip Chip Underfill

“Underfills” increase the mechanical stability between the chip and the circuit board and distribute voltages which occur locally over a larger area, which significantly extends the service life. In order to do this, a low-viscosity material is applied along the edge of the chip, which then fills the gap between the chip and the circuit board due to the capillary effect.

2K encapsulation

Encapsulation is always used when a particularly high level of protection is required. With the ProtectoXP, the volumetric operating principle of the applicators ensures that the correct quantity of material in the correct mixing ratio is delivered every time, irrespective of temperature or fluctuations in pressure.

Heat dissipation

Due to the continuous miniaturisation process in the field of electronics, less and less surface area is available for heat dissipation as time goes on. This makes an optimum transition between the cooling element and the component even more important. Liquid heat transfer media can adapt to the individual contours more effectively as fixed pads or foils and ensure safe heat dissipation, which significantly extends the service life of the components.

You can find more information on the dispensing and coating systems in the Protecto series here.