Individual process technology

The technical design of Rehm systems is largely determined by part dimensions, thermal mass, materials, process specifications and throughput volume and/or cycle times. Using our excellent technological know-how and many years of experience in plant and mechanical engineering, we design thermal system solutions that match individual applications precisely.

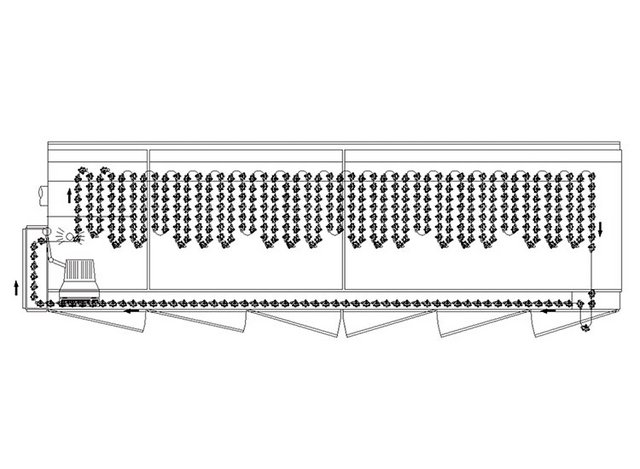

The Rehm RSS machines have a modular design that can be variably equipped with convection or IR radiators. For example, the heating system can reduce the cooling gradient to a minimum using additional underside heating.

Multifunctional reflow soldering systems for innovative backside reflow technologies

The backside-reflow technology was developed for complex, double-sided boards that are densely packed with SMD parts and that are not suitable for wave soldering. Selective reflow soldering and even manual soldering are therefore the only ways to solder thermally-sensitive THD.

Vacuum high-temperature soldering system

Our vacuum high-temperature soldering system with top loading is ideal for high throughput processes. The high-temperature soldering process is performed using forming gas exceeding 400°C. Clean soldering joints can also be achieved through a defined temperature-time-process with changing atmospheres.